Post-Tensioning System

ENGINEERING SPECIALTY

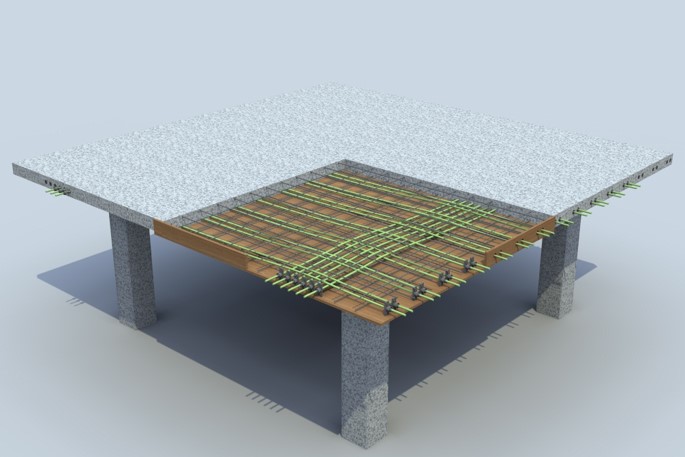

About Post-Tensioning System

Post-Tensioning System is a pre-stressed concrete method which increases compression force using high-strength cable or steel rods to increase the nominal strength of members. It takes advantage of the properties of concrete, which is strong when compressed, to improve concrete’s low tensile strength. Post-tensioning systems make slender and longer span lengths possible, with lighter members and a more economical structural system. Specifically, it is very effective to save story height in a slab system.

In general, post-tensioning systems can be classified into bonded and unbonded methods. Bonded post-tensioned concrete uses a tension cable or rod which is unified to the concrete using mortar filling after tensioning. It utilizes a larger number of tensioning members in a limited area. As a result, it is good for transfer members which require high strength, such as beams. The bonded method is popular in Southeast Asia, Europe, and Australia. With unbonded post-tensioned concrete, the tensioning stress is transferred by anchoring the tension cables or rods to the concrete. Each tension cable has its own anchor which is relatively small, making this a good method for slender members such as slabs. The unbonded method is popular in North America.

Advantages of the post-tensioning system include longer span lengths with smaller member sizes as compared to a reinforced concrete system. As a result, it is very effective for reducing story height and the need for cantilever systems. A post-tensioned section is more slender but will not crack, which would decrease the section’s strength. This results in outstanding performance in deflection and vibration. Additionally, the post-tensioning system is more economical by about 10-20% as compared to RC or steel systems.